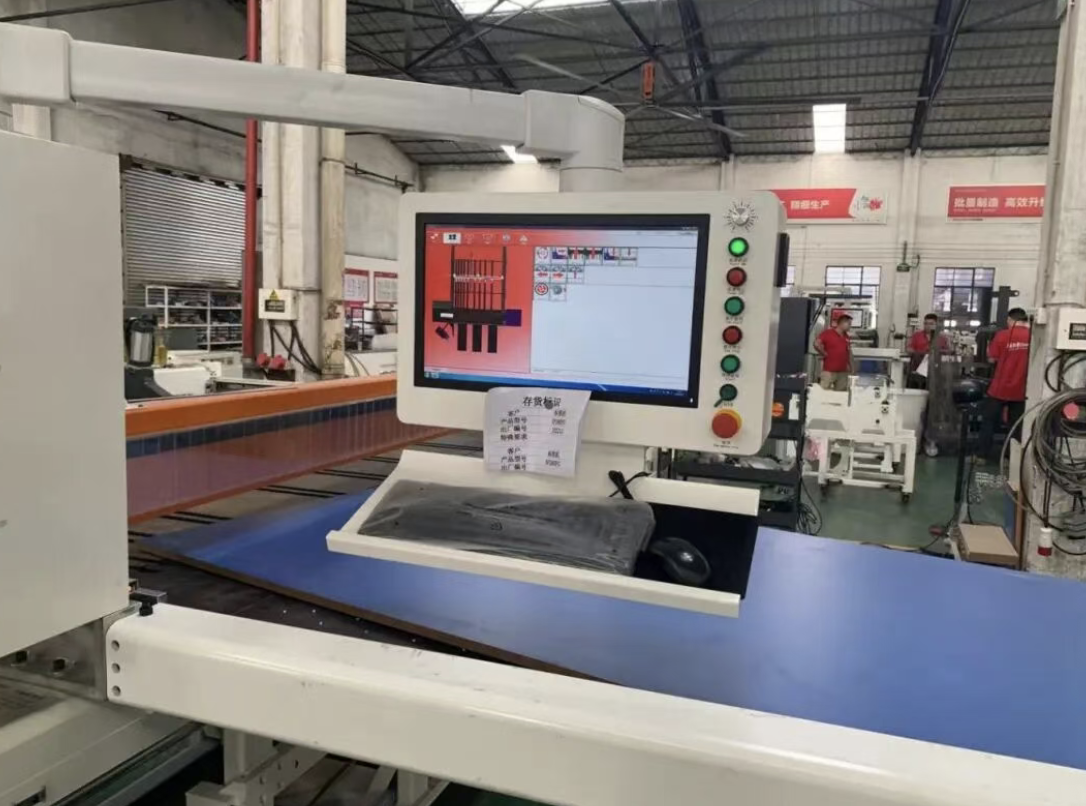

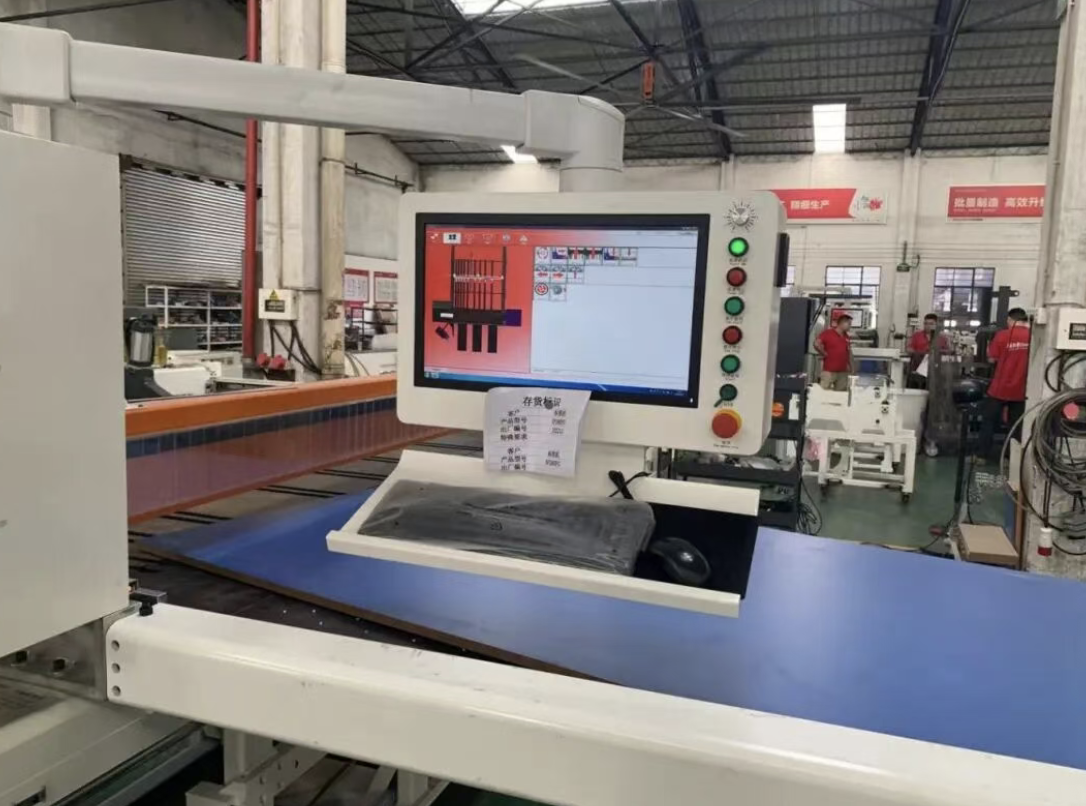

Vincanwo Group’s UNO Industrial Box PC is a fanless, compact embedded computing solution tailored for harsh industrial environments, empowering woodworking machinery with reliable control, real-time data processing, and seamless connectivity to drive intelligent upgrades and boost productivity. Below is a detailed breakdown of its core values, features, and woodworking-specific applications.

Core Advantages for Woodworking Machinery

Fanless Rugged Design for Harsh Shop Floors

Aluminum alloy chassis with wide operating temperature range (-20°C to 60°C), IP40 dust/water resistance, and anti-vibration construction to handle sawdust, oil mist, and constant machine vibration.

Fanless thermal design eliminates moving parts, slashing maintenance costs and maximizing uptime—critical for 24/7 woodworking production lines.

Flexible Computing & I/O for Precision Control

CPU options: Intel N95/N100, Celeron J6412, or Core i3/i5/i7 for tasks from basic CNC motion control to complex vision-guided cutting/edge banding.

Rich I/O: Multiple COM ports (RS232/485) for servo drives/encoders, dual Gigabit Ethernet, USB 3.0, HDMI/VGA, and optional fieldbus (PROFINET/EtherCAT) for seamless integration with CNC routers, edge banders, and panel saws.

Modular expansion (PCIe/PCI slots) supports add - ons like machine vision cameras for defect detection or AI acceleration cards for predictive maintenance.

Seamless Connectivity & Smart Integration

Supports Windows/Linux/Android OS, enabling compatibility with industry - standard woodworking software (e.g., CAD/CAM, nesting, and ERP systems).

Dual - LAN, Wi - Fi 6, and Bluetooth 5.0 facilitate real - time data sync with MES/ERP, remote monitoring, and OTA updates to minimize downtime.

Programmable GPIO and interrupts enable fast response to sensor inputs (e.g., material thickness, feed rate) for closed - loop precision control.

Compact Form Factor for Space - Constrained Machinery

Small footprint (e.g., 180×120×50mm typical) fits easily into control cabinets or machine enclosures, avoiding space conflicts with existing hydraulics/mechanics.

DIN - rail or wall - mount options simplify retrofitting into legacy woodworking equipment without major rework.

Key Woodworking Machinery Applications

| Machinery Type | UNO Industrial Box PC Use Cases | Value Delivered |

| CNC Routers | Motion control, tool path optimization, 3D carving simulation, real - time error compensation | 50% faster setup, ±0.01mm cutting accuracy, reduced material waste |

| Panel Saws | Automated size measurement, servo - driven positioning, batch nesting, dust extraction linkage | 30% higher throughput, consistent cut quality, lower energy costs |

| Edge Banders | Glue temperature control, feeding speed sync, edge alignment vision inspection | Zero edge defects, 24/7 unattended operation, reduced rework |

| Sanding Machines | Vibration monitoring, motor load balancing, surface finish quality analysis | Extended tool life, uniform sanding, predictive maintenance alerts |

ROI Drivers for Woodworking Manufacturers

Downtime Reduction: Fanless design cuts unplanned outages by 80% vs. consumer - grade PCs.

Labor Savings: Automated data logging and remote diagnostics reduce on - site technician visits by 50%.

Material Efficiency: Precision control slashes waste (plywood/veneer) by 15%–20% annually.

Future - Proofing: Modular I/O and upgradeable CPUs support AI - powered quality inspection or robotic material handling down the line.

Customization & Support

Hardware Tailoring: Customize CPU, RAM (up to 32GB DDR4), storage (64GB–2TB SSD), and I/O (e.g., 6COM ports for legacy machinery).

Software Integration: Pre - installed Windows 10 IoT/Linux with drivers for woodworking CNC software (e.g., ArtCAM, Vectric) and MES connectors.

Global Service: 2 - year warranty, 24/7 technical support, and on - site repair for critical production lines.

Why UNO Stands Out vs. Alternatives

| Feature | Vincanwo UNO | Generic Industrial PCs | Advantech UNO Series |

| Woodworking - Specific Tuning | Pre - tested with common machinery protocols; vision/CNC optimization | No industry - specific calibration | Limited woodworking software pre - integration |

| Cost - Performance | Competitive pricing ($135–468) with full customization | Higher cost for similar specs | Premium pricing; less flexible for small - batch customization |

| Lead Time | 7–15 days for standard models; 30 days for ODM | 30+ days | 20–40 days |

Vincanwo Group’s

UNO Industrial Box PC bridges legacy woodworking equipment and Industry 4.0, delivering the reliability, precision, and connectivity needed to scale smart manufacturing. It is ideal for both OEMs building new intelligent machines and manufacturers retrofitting existing lines for higher efficiency.