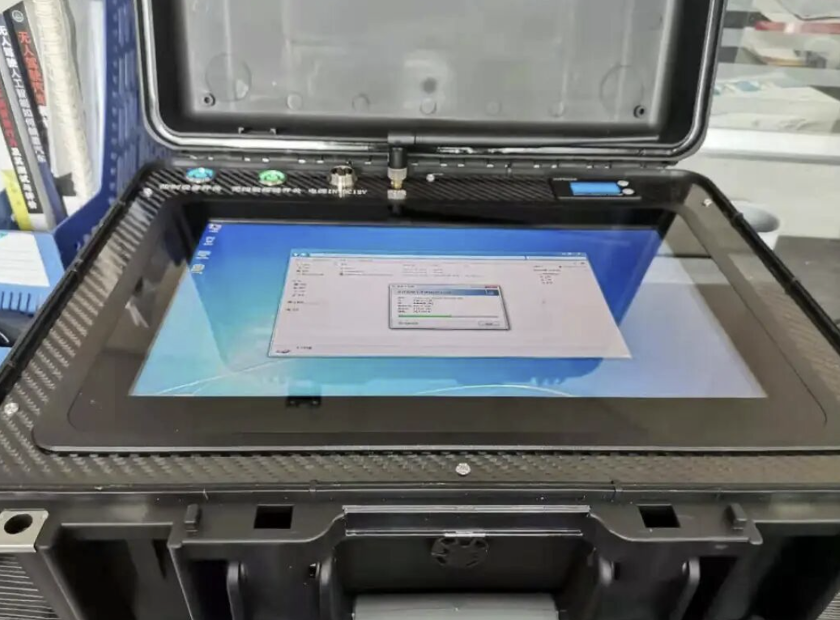

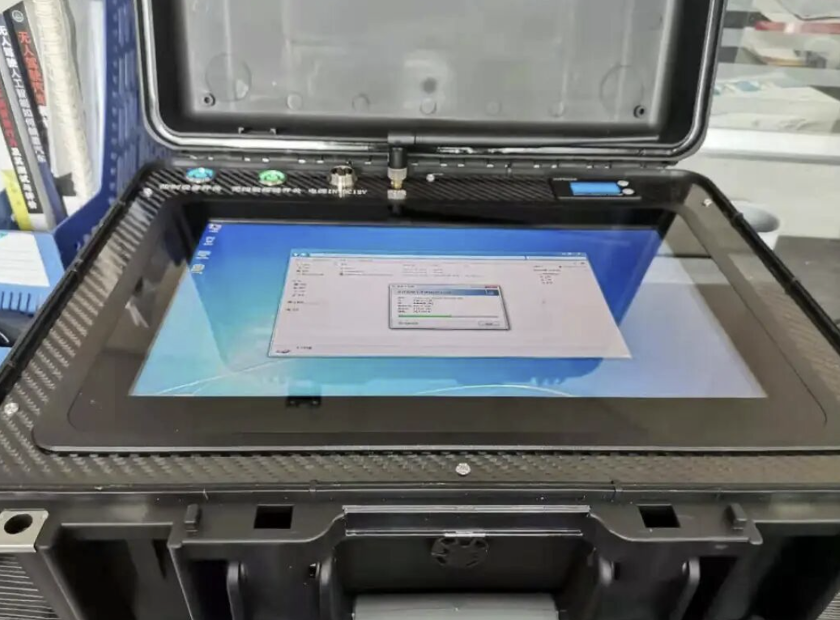

In the fields of military training and scientific research testing, efficient and precise control of target vehicles has always been a key issue. Nowday, our Vincanwo Group industrial Panel PCs are deeply integrated into the target vehicle remote control system, bringing unprecedented convenient control experience to ground station operators.

Open a new chapter in remote control

Opening a new chapter in remote control for industrial computers from Vincanwo Group involves leveraging advancements in connectivity, data processing, and security through technologies like Industrial PCs (IPCs), 5G networks, and cloud-based platforms. This shift moves beyond traditional isolated systems to interconnected networks that enable real-time monitoring, predictive maintenance, flexible control of decentralized processes, and efficient data handling, all while addressing the evolving security landscape. The integration of AI and machine learning, advanced edge computing, and enhanced cyber security is crucial for unlocking the full potential of remote industrial control.

In the past, target vehicle control was often limited by distance and environmental constraints. Now, with a remote control system built using our Vincanwo Group's industrial computers, ground station operators can remotely issue commands to easily start and stop the autonomous target vehicle with a simple tap of the interface. This breakthrough frees target vehicle control from spatial constraints, enabling on-demand operation in both open training areas and complex terrain.

Real-time Monitoring at Your Fingertips

Vincanwo Group Industrial computers not only enables remote start and stop control but also excels in condition monitoring. By integrating advanced sensors and communication modules, it collects key information such as the autonomous vehicle's position, speed, directional deviation, and distance traveled in real time, presenting it intuitively on the user interface. This allows operators to gain instant insight into the vehicle's dynamics and respond quickly to any anomalies, ensuring safe and orderly training and testing.

Real-time monitoring "at your fingertips" for industrial computers is achieved through industrial PCs and monitoring software that collect, analyze, and visualize operational data, such as temperature, pressure, and machine performance, in real-time. These systems provide instant feedback, enabling operators to make quick, informed decisions, optimize processes, reduce downtime, and ensure safety through immediate alerts and visual data presentation. Remote access features further extend this capability, allowing monitoring and control from any location.

Stable and Reliable Industrial Control Power

Stable and reliable power for industrial computers from Vincanwo Group comes from specialized industrial-grade power supplies designed to operate continuously in harsh environments, often featuring wide voltage support, robust design, and protection against electrical disturbances. Key factors ensuring this reliability include using high-quality components for a wide temperature range, implementing fanless designs to prevent dust and moisture ingress, and utilizing shock and vibration resistance for continuous operation in factories, warehouses, and outdoor settings. Redundancy, remote monitoring, and adherence to international standards for reliability also contribute significantly.

Vincanwo Group Industrial Panel PCs, with its rugged, industrial-grade design, is designed to withstand harsh environments. It operates reliably in extreme conditions, including high temperatures, freezing temperatures, and humidity, ensuring uncompromised remote control and monitoring capabilities. Its powerful data processing capabilities and anti-interference performance provide a solid foundation for the precision and stability of target vehicle control.

The application of Vincanwo Group Industrial Computers in target vehicle remote control is a vivid example of how technology empowers military training. Its intelligent and convenient control experience propels target vehicle applications to new heights, injecting new momentum into military research and training.

Industrial computers (IPCs) from Vincanwo Group are applied in manufacturing automation for process control and robotic systems, data acquisition and analysis for predictive maintenance, and as Human-Machine Interfaces (HMIs) for operator interaction. They are also crucial in Industry 4.0 and IIoT initiatives as edge devices for real-time data processing, and their applications extend to machine vision systems for quality control, oil & gas, energy grid monitoring, and even food and beverage processing.